1943

The year 1943 would be the high water mark for Steyr-Daimler-Puch, what had begun the previous year would take its full measure during 1943. A combination of a vigorous modernization and expansion with a loosening of ordnance regulations (lessening standards of fit and finish and the introduction of simplifications) would come together to significantly improve the company armaments output. Truck production more than doubled again, ball bearings nearly so and small arms would all rise markedly, – this is as much a product of a settling of production as lessening of acceptance standards. The prior years often saw changes in production, the moving of shops to accommodate construction projects, the moving of machinery to different factories, to Radom, Letten and Graz, all this took a toll on productivity.

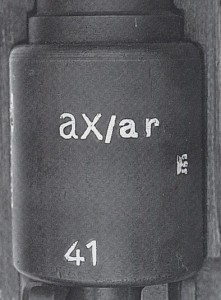

It was also during March 1943 that SDP entered into a special agreement with the SS, the leasing of barracks and labor at KL Gusen for production of rifle components, which would be assembled and tested at the main factory at SDP-Steyr. This relationship was far more involved than it seems at first glance; SDP had been intimately involved with slave/coerced labor since 1941, mostly on construction projects and the operations in occupied Poland where the company involved itself in the exploitation of Jews and Polish civilian labor. This new SS contract was actually quite controversial at the time, the German Army and Armaments Ministry was very much against this program, as it would be beyond their authority and oversight, – and it would be largely funded by money provided by the military. Very little is known about the parameters of the program, although it was certainly outside the scope of military armaments production and the rifles were never intended for military purposes.